Sheet metal welding

Minifaber performs MIG welding, TIG welding and resistance welding, projection welding, robotic MIG and TIG welding and laser welding.The know-how acquired over the years, the constant innovation process and the multifunctional machinery allow Minifaber to offer sheet metal welding services according to the customer's specifications.

On this page, we will discuss:

- Types of welding processes

- Welding metals: the metals that we process in Minifaber

- Tips for welding sheet metal

Types of welding processes

Minifaber performs several types of welding processes: MIG welding, TIG welding, resistance welding, projection welding, robotic MIG and TIG welding and laser welding on various metallic and aluminum alloy surfaces as well as on stainless steel and iron.

MIG welding

MIG welding, also called MAG welding, is a continuous wire welding process where a shield gas ensures firing bath protection. MIG or MAG welding is used where high productivity and high flexibility of use are required. While MIG welding requires the use of inert gas, MAG welding is carried out through an active gas. MIG welding can be also performed on thin metal, such as thin steel or aliminum.

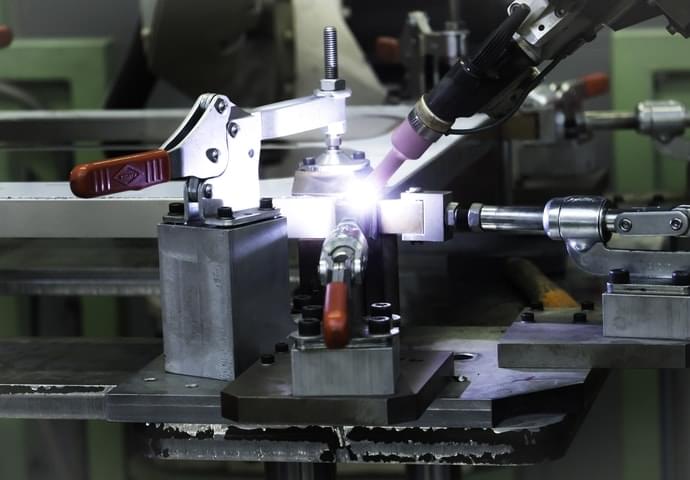

TIG welding

TIG welding is one of the most popular welding methods since it provides high quality components. Especially indicated to weld thin parts, it can be used for both continuous and spot welding.

Resistance welding

Resistance welding is a metal fusion welding technique where the material is heated by an electrical resistance. Generally used to weld iron and steel, resistance welding guarantees high quality standards on welded components while ensuring time and cost savings. If you want to learn more about resistance welding, we will explain everything to you.

Projection welding

Projection welding requires studs to be placed on the metals to be welded. During the metal welding process, the welding current is focused on the stud that heats to obtain complex welds, with final results that ensure excellent quality at low costs. Basically, projection welding is a type of resistance welding that uses projection.

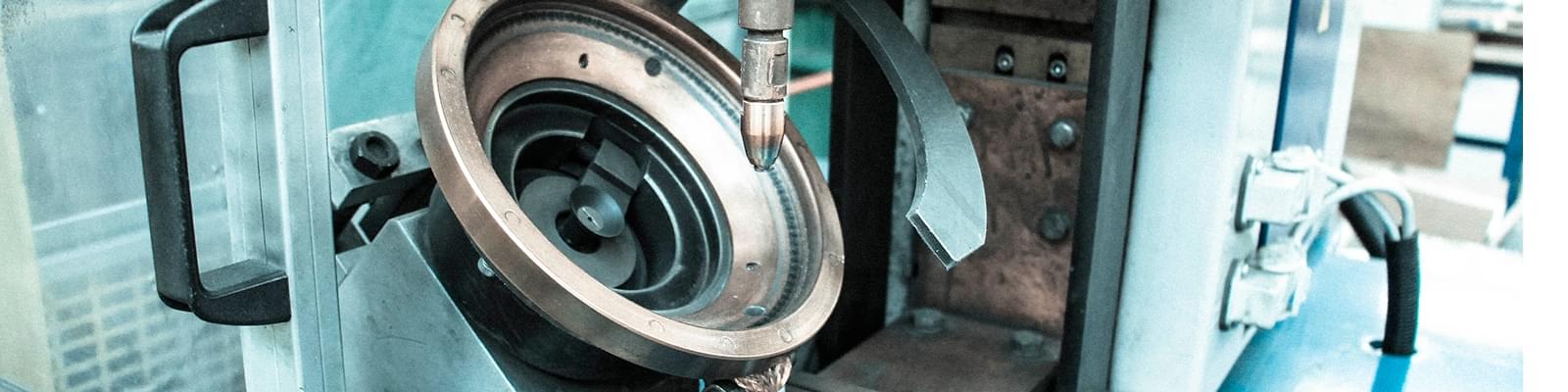

Robotic TIG MIG MAG welding

Robotic welding is performed by programmable industrial robots. Mainly used in situations that requires repeated welding, it guarantees repeated precision that is hard to achieve with manual welding. Greater precision and higher productivity are the main advantages of robotic welding.

Laser welding

Laser welding allows metals and metallic alloys to be welded, creating a thin and deep weld, with reduced heat deformations thanks to the reduced heat, even on materials that could not otherwise be welded. Precision, cleanness, minimal heat input, and fast manufacturing are just a few of the advantages of laser welding.

Welding metals: the metals that we process in Minifaber

The mentioned welding processes apply to a wide range of metals and sheet metal components that can be welded to create semi-finished and finished products. Through these processes, Minifaber can provide welding of iron, aluminum, stainless steel and copper.

Iron welding

Iron welding is one of the most required welding processes, as the material is widely employed in several industrial sectors. Thanks to the cutting-edge machinery and the extensive know-how raised through the years, Minifaber can provide iron welding services with the highest cleanness and precision. There are 5 different ways to carry out iron welding: Minifaber will help you choose the right one!

Aluminum welding

Renowned for its ductility, lightness and oxidation resistance, aluminum is employed in every sector in which these qualities are required, such as the aerospace sector and the transport sector. Minifaber is specialized in various types of aluminum welding: aluminum MIG welding, aluminum tig welding and other welding processes to manufacture aluminum according to the desired output.

Stainless steel welding

Stainless steel is a special steel alloy that boasts important qualities such as rust resistance, corrosion resistance and high hygiene standards. For this reasons, stainless steel is widely employed in the food industry. Minifaber provides stainless steel welding services for any specific requirements, and offers three different services of stainless steel welding.

Copper welding

Copper is employed in the electrical and electromechanical sectors for its high conductivity and ductility. Copper welding is among the services provided by Minifaber for national and international customers.

Tips for welding sheet metal

Welding is defined as the process that joins together two pieces of metal, glass, or thermoplastics with similar melting points and compositions using fusion. Today, there are many welding techniques that can be chosen, each suitable for a particular sheet metal alloy or application. Here you can find some tips for welding sheet metal in the right way:

- Match the metal with the right process - Before there were any arc welding processes or oxy acetylene gasses, there were simpler practices. Thankfully, modern technology has made welding the toughest metals easier. However, each sheet metal requires its own technique to be welded. For example, aluminum and other thin alloys should be welded by TIG technique, while steel or iron require MIG/MAG welding. Choosing the right one is our job.

- Choose the right company - Entrust your welding to a reliable partner. How to evaluate it? Pay attention to the type of machinery used, the training of the team, the product guarantees offered. Minifaber is always up to date on the latest technologies and techniques in the sheet metal welding industry.

- Do a test on metal - Before you start series production welding, do a test run on the metal. For example, by relying on Minifaber, you can have a prototype of your semi-finished or finished product.

- Adjust heat - Heat is the biggest factor when welding sheet metal. Adjusting it properly will ensure you get a perfect weld, while going too much will only cause you to burn through the material. That’s why in Minifaber we use different types of welding depending on the metal.

In the case of thinner sheet metal or highly ductile metals (such as aluminum or copper), even more care must be taken in the sheet welding process.

How to weld thin sheet metal

Heat is essential when welding thinner material. Minifaber machines can control the amount of heat, welding any sheet below 0.8 mm without any problem. With this type of sheet metal, TIG welding is the most suitable technique, but we evaluate case by case depending on the result required by the customer.

Are you interested in metal welding? Read our posts to learn more.

MIG Metal welding: 5 tips to make a perfect job - posted on Tuesday, 07 January 2014

7 strange stuff created by metal welding - posted on Tuesday, 21 January 2014

How to select the correct metal welding process, MIG or TIG? - posted on Tuesday, 04 February 2014

Minifaber welds metal for the following industries:

- Electromechanics

- Vending

- Kitchen robots

- Medical

- Gas distribution

- Professional lighting

- Home appliances

Minifaber has evolved to become the only company able to design and manufacture the complex, assembled end products no one else can.

Find out more