Steel bending

Due to the hardness of the material involved, steel bending requires a precise process in order to obtain a perfect result. But what do we mean with steel bending, and how does it work? Discover it on this page, together with Minifaber services. In fact, we have been operating in the field of cold metal working for more than fifty-years, and offer steel bending for industries operating in the most diverse fields worldwide.Table of contents:

- What is steel bending?

- Minifaber’s services

- Our machine fleet and its advantages

- Things to consider before starting the bending process

What is steel bending?

Also known as press braking, flanging, folding and edging, bending is one of the most commonly employed cold working methods in the sheet metal industry. More in detail, steel bending is the deformation of steel to an angular shape.

Relatively low production costs, high availability, and its various mechanical properties have raised the popularity of steel in the most diverse applications. As a consequence, the request for steel bending has notably increased in the years.

Minifaber steel bending methods

There’s a few methods for bending steel. Here are the ones available at Minifaber’s:

#1 Steel bending with V-die or air bending

V-bending is definitely the most common way for bending steel when you need to obtain corners until 90 degrees. It requires the use of a punch and a die, and can be divided into three subgroups: air bending, coining and bottoming.

#2 U-bending

This kind of steel bending involves the use of cylinder molds, and is most applied for bending steel U-channels.

#3 Rotary steel bending

This technique creates tight radii and it is most used for complicated bends in the machine and parts industry. During rotary steel bending a bender curves a flat steel surface through a rotary die – more precisely a cylinder.

The big advantage of this technique is that it does not scratch the metal surface.

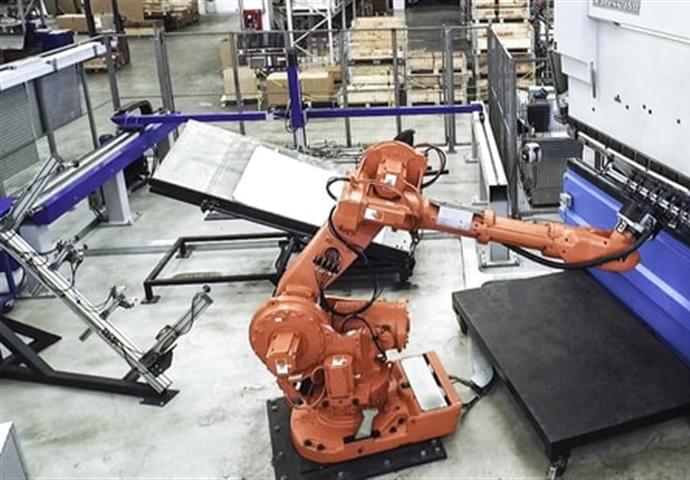

Minifaber machine fleet

Steel bending takes place by means of a bender, a machine that uses a mold to exert a pressure on the flat plate so as to obtain the desired shape.

Minifaber uses highly technological and precise CNC machines to carry out the process of steel bending. The biggest advantage they provide lies in the fact that they can bend big quantities as well as a single piece exactly with the same precision.

In fact, by equipping them with the right components, we can ensure you get the exact kind of steel bending you need.

Our machine fleet is composed of 7 bending machines ranging from 30 to 180 tonnes: depending on the product to obtain, we know which one to use.

Things to consider before starting steel bending operations

Obviously, before starting the bending operations, a reliable supplier needs to evaluate a few points:

- the metal properties

- the stress caused from the previous process

- the kind of the edges you want obtain

- the length and the thickness of the workpiece

- the processing temperature

Springback and inside radius

After the load is lifted, the piece of steel naturally springs back a little. The solution is, in fact, quite simple: the metal is bent beyond the required angle so that it takes the desired shape after springback.

Another thing to keep in mind when dealing with steel bending is the inside radius. The larger it is, the bigger the springback is – however, a sharp punch can give a smaller radius.

Minifaber has evolved to become the only company able to design and manufacture the complex, assembled end products no one else can.

Find out more