Metal welding: advantages and disadvantages of the most used technologies

Metal welding is a widely used process in the world of cold sheet metal working, but every business can perform it with different processes and technologies, depending on the customer requirements. Based on the customer needs, we find many different weldings both from an aesthetical point of view and as far as their features, costs and working times are concerned. Here is a brief excursus of the different kind of the most used metal welding, with advantages and disadvantages of each of them.The welding is the technique with which the continuity of the metallic material is realized between the two pieces to be joined. The continuity can essentially be obtained in two ways:

- By liquid-liquid contact and connection, i.e. by melting the two edges of the joint (laser welding, TIG welding, MIG/MAG welding, resistance welding);

- By solid-solid contact, ie without melting; in this case the connection is obtained by mutual diffusion between the materials of the two flaps, which always remain in the liquid state.

In this article, we will delve into:

Laser welding

Laser sheet metal welding can perform thin and deep weldings, extremely resistant and, in the same time, aesthetically nice. This is possible because, differently than other kinds of metal welding, laser welding does not add material to the sheet metal piece, and rarely does it create weld beads or significant residuals. On the other hand, though, laser welding needs excellent skills to be performed at its best: the pieces alignment must be perfect, as well as the regulations of the machines, making it a very difficult welding: that is why not all the businesses that provide sheet metal working can grant laser weldings properly carried out.

TIG welding

TIG welding is the most used process of welding. “TIG” stands for Tungsten Inert Gas and it denotes a kind of arc metal welding that is performed with the use of gases and makes possible to heat and melt together two metal sheets with or without filler material. TIG welding can perform resistant weldings in particular with thin components, but it is less effective with thicker components, as to gain a result you have to perform more than one TIG welding.

MIG/MAG welding

MIG/MAG welding is currently the most economical metal welding process, as the machinery to perform this kind of working is unexpansive. As for TIG welding, it requires the use of an inert gas in the MIG process, and of an active gas in the Mag process, but, differently than the metal welding explained before, it is a continuous wire welding. This feature makes it ideal when a high productivity is required, but the result is less resistant and less beautiful than the one gained with a TIG welding or a laser sheet metal welding.

Resistance welding

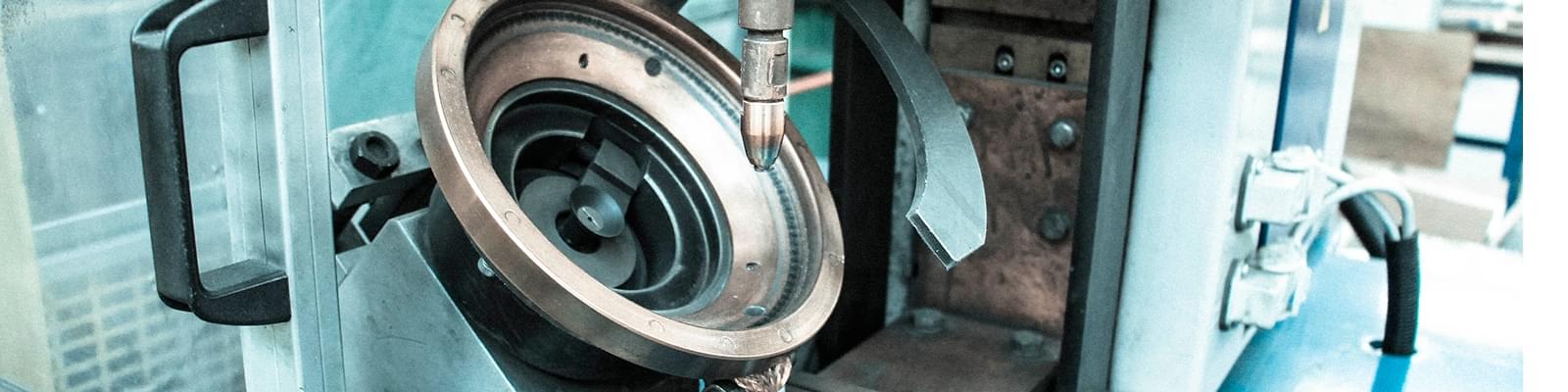

Resistance welding works thanks to the heating of the material gained with electric resistance and, applying a pressure, can weld two sheet metal pieces together, heating only a little part of the components. It is a kind of metal welding that is often automated: for this reason, resistance welding is mainly used in mass production, as in the automotive field or in the production of household electrical appliances.

Recap: Advantages and disadvantages of welding

First and foremost, it is important to underline that any kind of welding presents its pros and cons. For this reason, assessing its effectiveness must include an evaluation of the components that have to be welded.

In the light of this, let’s review the advantages and disadvantages of every type of welding technique.

Laser welding

Laser sheet metal welding is perfect if you wish to achieve both thin and deep welds. This process not only displays exceptional strength, but is also of great aesthetic appeal.

However, it demands a high level of know-how for optimal execution and, consequently, not all sheet metal companies can ensure high precision laser weldings.

In this case, it is imperative to find the right combination of both expertise and design, in order to guarantee results that can actually meet our customers’ demands.

TIG welding

TIG welding is one of the most common procedures and it is carried out using a tungsten electrode protected by an inert gas. It can be performed with or without filler metal, but it is certain that this kind of metalwork gives to the operator much more control over the entire process.

Another reason to choose TIG welding resides in its versatility. In fact, it could be used for all applications. Moreover, one of its features is that metals that have been welded using the TIG process don’t need cleaning afterwards.

Unfortunately, there are some disadvantages, as well. Being so precise, the TIG welding technique is not performed as fast as it should be, also due to the fact that it is a process which requires a high level of customization.

MIG welding

The MIG/MAG welding process is the most convenient in terms of price/quality ratio. It is the perfect solution in case you need an efficient and highly productive method for your activity.

On the other hand, the results are not as aesthetically pleasing as they could be. Moreover, the resistance of the end product is another critical factor to consider when choosing which type of metalwork to opt for.

Resistance welding

In resistance welding, heat is provided by the passage of current between two electrodes. For this reason, this method is quite fast, heating only a small part of the components and not the metal as a whole. This makes the technique ideal for high rate mass production, as most of the operations are automated.

Unfortunately, resistance welding requires conductive material in order to allow electric current to flow and space for the electrodes.

Choosing Minifaber, you can be sure that before starting production, every component is carefully considered, in order to identify the most suitable welding for each occasion.