Sheet metal processing: 4 sectors that would not exist without it!

The sheet metal processes offered by Minifaber are fundamental for creating the products that we all use every day. Are you wondering what they are? Here is a brief description.

Home appliances, excluding none

The frame of your TV is made through sheet metal processing. Your food processor or planetary mixer most likely have a container produced through sheet metal processing. The inner mechanisms of your vacuum are made using components derived from sheet metal processing. Your refrigerator, oven, air conditioner... we could go on forever! In fact, Minifaber processes are at the base of the structures and support mechanisms of just about every home appliance, and even if you can't see them, these metal components are fundamental for their proper functioning.

Sheet metal processing for the lighting sector

It doesn't matter if you choose a floor lamp or recessed spot lights, it is almost certain that the lights you turn on and off every day have an aluminum body made with blanked sheet metal, bent and treated on the surface to give it the most suitable appearance for your environment.

What you didn't know: Minifaber boasts many years of experience in the lighting sector, and the company even co-designed a professional projector that was used to illuminate the 2012 Olympic Games in London.

Gas meters are also made through sheet metal processing.

A gas meter cannot be constructed in plastic, because it does not provide the watertight quality necessary for these devices. The inside of the meter and the connecting sleeves are therefore made through sheet metal processing, and require careful inspections, like those performed daily at Minifaber, to prevent rupture and/or leakage.

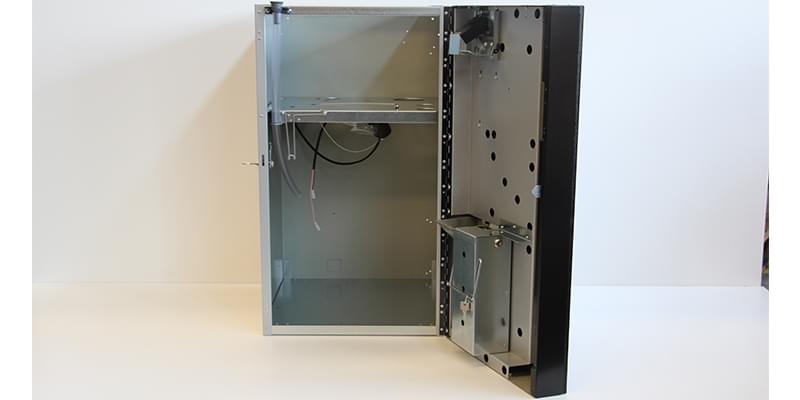

Processes for the vending sector

We are sure that after you read what we have to say you will never drink another "coffee machine" coffee without thinking of us and our processes: in fact, coffee vending machines, as well as water and snack vending machines, are all produced by a sheet metal process based on blanking, bending and welding processes that transform a common piece of sheet metal into your coffee break partner at the office.

In all of these sectors, and many others, the professionalism of Minifaber becomes a fundamental aspect to create finished, complex and assembled products that generate high added value, ready to be distributed on the market.