Sheet metal stamping

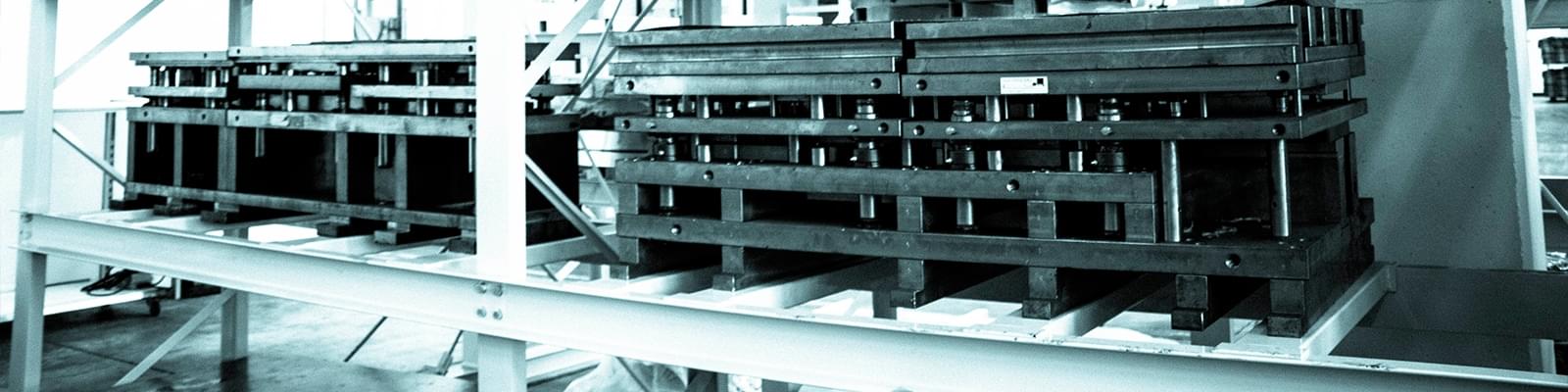

Minifaber carries out sheet metal stamping processes that are completely customized according to the needs of the client.Thanks to a team of technicians specialized in the design and creation of moulds, Minifaber can provide in-house all the processes of sheet metal stamping, granting a high standard of professionalism and flexibility in meeting all the needs of the customer.

Customized sheet metal stamping

Customization is indeed the prominent quality of Minifaber’s sheet metal stamping: relying on its technical and design team, the company produces the moulds required for the operation needed, designing them one by one according to the specific requests of the client. A process that is carried out inside the company through all its phases, granting a significant saving of time and a final, top quality output, completely customized.

Strengths: a Technical Office and a cutting-edge machinery

Two are the strengths that determine the high quality standards of sheet metal stamping by Minifaber: on one hand, as mentioned before, the presence of a Technical Office with expert and passionate people, depositary of a true treasure of knowledge gathered up during years of experience. A professional know-how that always lets the company position among the top players in the field of sheet metal working.

On the other hand, Minifaber’s flagship is the cutting-edge machinery, constantly upgraded and enriched with important investments that keep the company at the top as far as innovation is concerned, in the field of sheet metal stamping and all the related processes of metalworking.

Sheet metal stamping process: high level of computerization

One other secret of the excellence of Minifaber’s sheet metal stamping is the high level of computerization that the company chose to integrate all its activities. Besides being a necessary aid during the design of the moulds, Minifaber’s IT systems also provide the integration and dialogue process of the machinery with the advanced operating systems that the technicians use to design and control the stamping process. The result is a unique, interconnected digital environment that breaks the barriers between the virtual designing and the realization of the product, optimizing time, cost and output quality of sheet metal stamping.

Finished or semi-finished products

Thanks to its team and to the never-ending process of innovation, Minifaber can grant today extremely reliable and precise services of sheet metal stamping, creating finished or semi-finished products capable of fully satisfying the expectations of the customer. Each product is also studied to optimize all the stamping phases, reducing the costs and the time of production. A winning strategy that made Minifaber one of the most important players in sheet metal stamping and in sheet metal working.

Minifaber carries out sheet metal stamping for the following industries:

- Electromechanics

- Vending

- Kitchen robots

- Medical

- Gas distribution

- Professional lighting

- Home appliances

Minifaber has evolved to become the only company able to design and manufacture the complex, assembled end products no one else can.

Find out more