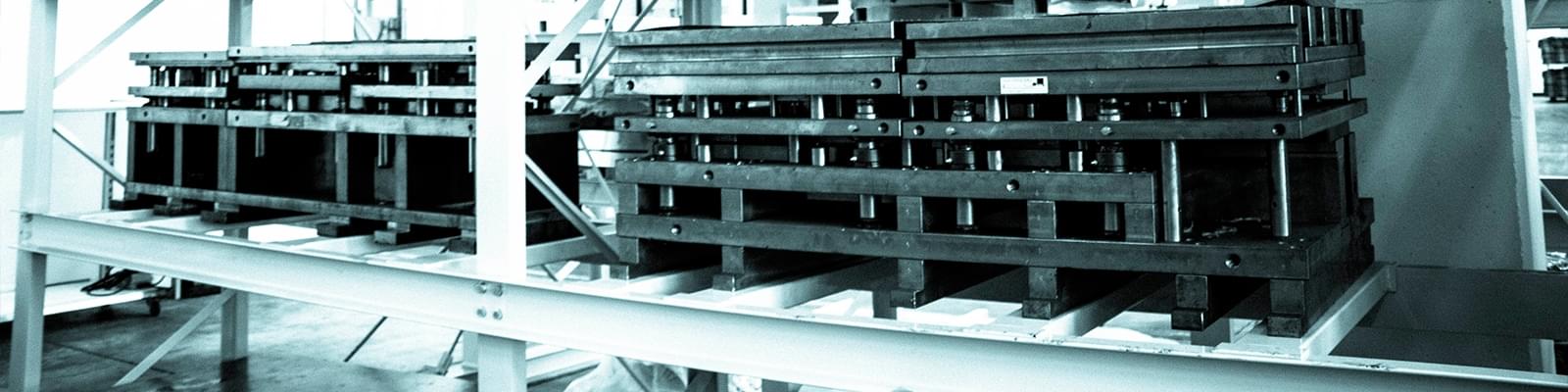

Cold metal stamping

Minifaber provides cold metal stamping for the production of finished or semi-finished products in accordance with the specific needs of the customerMinifaber has been carrying out the process of cold metal stamping and sheet metal working for over fifty years, always committing with high professionalism in meeting the specific needs of any customer. Who chooses Minifaber finds a complex and competent reality that always grants the highest level of customization to the finished or semi-finished products requested, studied with the customer since the design process.

Understanding cold metal stamping

Cold metal stamping is a widely used process in the field of sheet metalworking, offering precision and versatility in the fabrication of various components and products. This technique utilizes specialized machinery and tools to deform and shape metal sheets without the need for excessive heat, ensuring minimal material waste and maintaining the integrity of the metal's properties.

It involves the utilization of a mechanical press to exert immense force on a metal sheet or strip, causing it to undergo plastic deformation. This deformation process occurs at room temperature, making it distinct from hot stamping methods that require elevated temperatures. The cold stamping process consists of several stages, including blanking, piercing, bending, forming, and coining, which can be tailored to achieve the desired shape and dimensions of the final product.

Advantages of cold metal stamping

- Precision: Cold metal stamping offers exceptional precision, allowing manufacturers to produce intricate and complex parts with tight tolerances. The mechanical presses used in this process are capable of exerting uniform force, ensuring consistent and accurate results throughout the production cycle.

- Versatility: One of the key advantages is its versatility. This technique can be applied to a wide range of metals, including stainless steel, aluminum, copper, and various alloys. It enables the production of components in different sizes and thicknesses, catering to diverse industrial requirements.

- Cost-effectiveness: It also offers a cost-effective solution for high-volume production. The process allows for rapid and efficient manufacturing, reducing labor costs and increasing overall productivity. Additionally, the minimal material waste associated with cold stamping contributes to cost savings.

Applications and metal types

The company can perform today cold stamping for many industries, among which electromechanical, medical, vending, home appliances and kitchen robots, besides the professional lighting and gas distribution fields. A wide range of applications that made Minifaber a leading player as far as the variety of the service is concerned, not to mention the quality and competence that have always been the top qualities of the company.

Besides the diversification of industrial applications, Minifaber has also diversified the metals processed, that vary today from iron to aluminum, from copper to stainless steel, up to brass and special alloys for industrial usage.

Choose Minifaber if you look for a top quality service of cold metal stamping with wide possibilities of customization, whose reliability and precision are today confirmed by a many customers in any productive industry.

Minifaber carries out cold sheet metal stamping for the following industries:

- Electromechanics

- Vending

- Kitchen robots

- Medical

- Gas distribution

- Professional lighting

- Home appliances

Minifaber has evolved to become the only company able to design and manufacture the complex, assembled end products no one else can.

Find out more