Breadcrumb

- Home

- Blog

Blog

The latest news from the world of sheet metal cold processing

Minifaber has established itself as one of the most efficient laser cutting companies in manufacturing solutions for processing metals such as aluminum, stainless steel, ferrous materials and…

MIG welding aluminum can become a real challenge if the appropriate machinery is not used and the process is not carried out with care. At Minifaber we specialize in metal cold working and this…

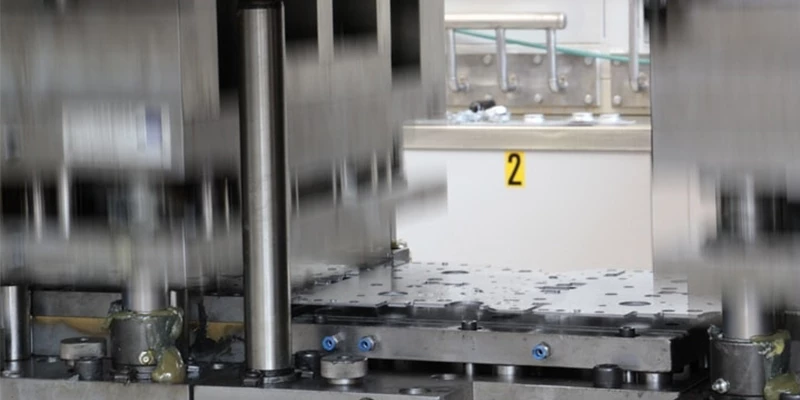

Are you looking for a company that specializes in tailor-made construction of blanking moulds?

Then you are in the right place! Since 1960, Minifaber has specialized in the cold working of…

Sheet metal cutting is a cold mechanical process, particularly suitable for large production quantities. Used to obtain both semi-finished and finished products, blanking depends on the combined…

The cutting-edge technology put in place by Minifaber, specialized in metalworking processes, allows it to accurately cut and bend sheet metal

Thanks to its experience and technical expertise, Minifaber is capable of producing custom metal molds either from scratch or using an existing design.