Breadcrumb

Steel welding: here's how to avoid imperfections in joints

How do you professionally weld steel? What are the most common imperfections in welded joints? The Minifaber experts will tell you all you need to know about steel welding and its applications.

To avoid imperfections in steel welding joints, attention must be paid to all steps of the process, from design to finishing. Incorrect steel welding can reduce the corrosion resistance and mechanical strength of the joint.

Minifaber, thanks to its experience, is able to make impeccable steel welds: here's how.

Steel properties

When we talk about steel welding, we usually mean the stainless-steel welding, one of the most popular due to its corrosion resistance properties; stainless steel can be welded with other stainless steel or with carbon steel. However, the ability of steel to be welded is not always the same, because it varies according to the composition of the material.

Stainless steel melts at a temperature of around 2372-2732°F yet, containing high amounts of chromium that oxidises in contact with oxygen (passivation), it can be difficult to combine with other pieces. It is therefore necessary to remove the oxide layer before welding, using a special brush and flux.

Types of steel welding

Steel can be welded in different ways:

- TIG – very suitable for creating high quality joints and perfect for welding pieces of reduced thickness;

- MIG/MAG – ideal when high productivity and flexibility of use is required

- With coated electrode – where the weld pool is protected from slag.

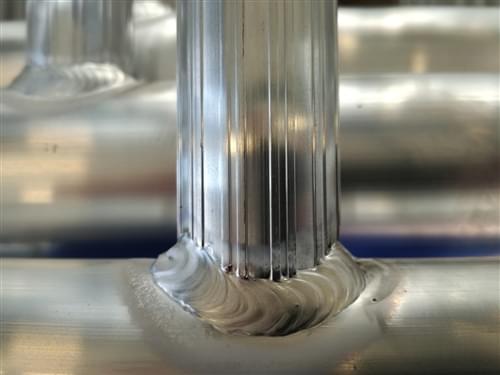

How to avoid imperfections in steel welding

To prevent welded joints from being subject to corrosion or fragility, or to have an irregular appearance - differences in the regularity of the mesh, surface slag, concavity or convexity of the joint, splashes, etc. - care must be taken in all the steps of the procedure:

- Check the oxidation status of the steel surface

- Choose the correct welding method

- Rely on welders with expert dexterity

- Carefully choose the geometric profile of the stock

- use an adequate flow rate and a correct welding speed

- Optimise the protective gas

Even the post-welding treatment is important: it is essential to clean the joint and remove stains, slag or other imperfections to ensure resistance to corrosion (brushing and pickling). If there are splashes, porosity or cracks, they should be removed mechanically.

Read more about Minifaber welding processes: Robotic welding: the best choice for mass production

How to check the quality of welded joints

There are different ways to check the quality of weld joints:

- Visual inspection - check that the joint complies with the project specifications, that there are no distortions or other visible defects

- Non-destructive tests – surface control with special liquids or volumetric control with x-rays/ultrasounds

- Destructive tests – they destroy the joint to test its resistance to traction, bending and resilience and to judge its metallurgical properties.

Steel welding applications

At Minifaber, we provide a welding service for stainless steel - MIG, TIG, and a protected electrode – for a wide variety of applications. We produce semi-finished parts or finished and already assembled products, intended for different sectors: mechanical, automotive, engineering, pharmaceutical-medical, household appliances, vending, lighting, plumbing, etc.

You can request steel welding both for small quantities and for larger loads; in the second case, you can also choose to stagger the production, dividing it into the periods you prefer.