Breadcrumb

Steel stamping in Bergamo: Minifaber exceptional quality

Minifaber is a company headquartered in Bergamo that specializes in steel stamping. We can help you discover how our services can benefit you.

Minifaber, a company headquartered in Bergamo, specializes in cold steel stamping to produce semi-finished or finished products based on specific customer requests.

For over 60 years, Minifaber has been creating value for its customers through the cold processing of metals, including steel stamping, a technique that requires high-level machinery and molds, and an experienced team.

In this article you will find more about:

- Our solutions for steel stamping

- Our specialized team and machines in Bergamo

- The computerization in Minifaber

- The steel stamping process

- The excellence of Minifaber, a company in Bergamo that operates worldwide

Minifaber steel stamping solutions in Bergamo

Our Bergamo-based company has developed considerable expertise in the application of highly flexible machinery for the steel stamping process. We are able to produce a wide range of molds, including:

- Drawing and blanking dies

- Progressive dies

- Block dies

- Transfer dies, through which we have exponentially diversified and refined the metalworking process.

Our focus on diversification and improvement of the metalworking process has allowed us to offer cold stamping solutions for various production sectors, including electromechanical, medical, vending, household appliances and kitchen robotics, professional lighting, and gas distribution.

The team and machinery suitable for steel stamping

Thanks to the highly competent in-house Technical Office, Minifaber designs and produces custom molds necessary for the processing of steel and stainless steel. We use state-of-the-art machinery for the production of cold metal components, which also includes the new 3D laser machine capable of creating samples or small series, offering greater flexibility in the production of complex metal parts.

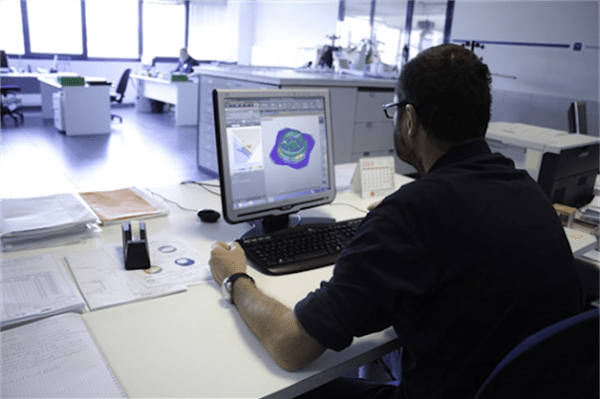

Computerization in Minifaber, how our computer systems control the stamping processes

Not only do we have state-of-the-art machinery, but Minifaber, which specialized in steel stamping in Bergamo, manages the customer's product design in 3D format through cutting-edge software that virtually simulates the bending and stamping process. Once the ideal solution is found, the part is then managed by the development software, which takes into account all the parameters chosen during the simulation (type of cavity and blade, blade radius dimensions, material characteristics, etc.). This results in the development of the part to be passed on to the post-process of the molds.

How is stainless steel stamping carried out?

The stainless steel stamping process takes place entirely at our facility in Bergamo and relies on a particular cold-working technique. Thanks to this methodology, we are able to produce complex metal parts with high dimensional accuracy, while guaranteeing high productivity at low costs. This process is based on a series of stages:

- Virtual design phase of the stamping dies, performed by our software.

- Preparation of the material.

- Actual stamping process, in which the material is inserted into the die and subjected to a force that shapes it according to the desired form.

- Finishing phase, when the parts undergo a series of operations such as deburring, cleaning, and painting.

Finally, the product undergoes a series of quality checks to ensure that it meets the specific requirements of the customer.

The excellence of Minifaber, a company from Bergamo operating worldwide

Minifaber, a company based in Bergamo, was founded in 1960 and has become, in over 60 years, a wealth of knowledge, innovation, and technology in the field of cold metal and steel stamping, which allows customers to meet every specific need, even the most complex. From Bergamo, we have expanded all over the world, supplying European and non-European companies and establishing ourselves as a leader in the industry. We don't say it, our customers give us the strength and motivation to always improve!

We are able to produce semi-finished and finished products, following the entire process internally, from design to production of the final product. Our approach is always oriented towards listening to the customer's needs, to deliver complex and assembled parts that no other company is able to produce.