Breadcrumb

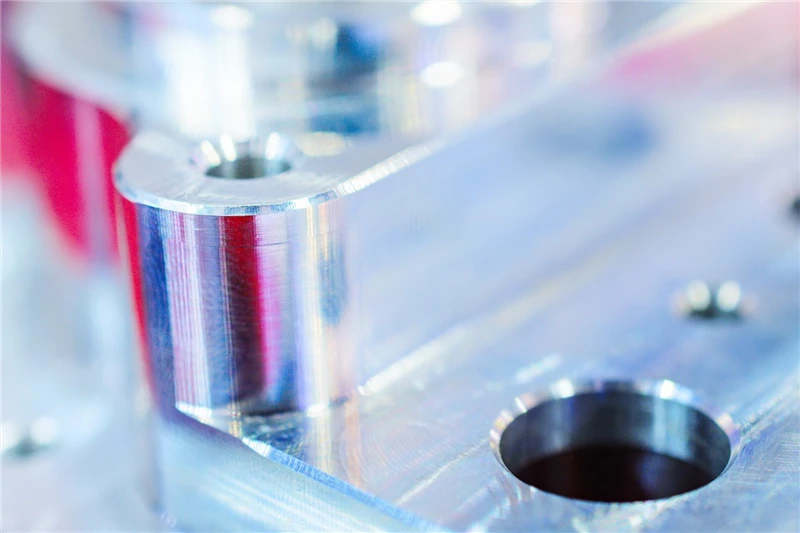

Aluminum processing: the benefits of cold working

Aluminum is a very versatile material and its properties are further enhanced if cold worked, guaranteeing multiple benefits. The Minifaber staff reveals all the secrets of aluminum processing.

There are many and various types of aluminum processes that can create a semi-finished or finished and assembled part. At Minifaber, we perform all the main aluminum processes:

- blanking

- bending

- drawing

- punching

- welding

- laser cutting

- surface processes.

Let's take a closer look but first, let's briefly discuss aluminum properties and the benefits of cold moulding.

Aluminum properties

Aluminum is a highly appreciated and widely used material thanks to its intrinsic properties: lightweight, malleable and ductile.

This means it has a very low specific weight that well resists mechanical forces (guaranteeing excellent distortion before breaking) and is easily reduced into thin sheets; consequently, aluminum processing is less complex than others such as, for example, steel processing. This permits to have a large number of possibilities for aluminium sheet finishes.

These properties, that make this material attractive to many sectors – from mechanics to cosmetics, are even further enhanced when aluminum is cold worked, like in aluminium punching.

Aluminum cold working

Aluminum cold working enhances the qualities of the material and adds numerous benefits to the process in terms of efficiency; in particular, cold moulding aluminum guarantees:

- material savings, because the part is moulded without removing parts of the material;

- process time savings (processes are quick and do not require secondary processes);

- consequently, product costs reduce;

- part properties are optimised, making the part easier to machine and even more resistant.

Aluminum processing with Minifaber

At Minifaber, we expressly cold mould metals, including all aluminum processes. Our machine fleet and the skills of our staff allow us to offer all the main aluminum processes: blanking, bending, drawing, punching, welding, laser cutting and various surface processes.

Our strength is our flexibility; we can meet your any need, with staggered productions for both large and small quantities. We can supply you with semi-finished or finished aluminum products, complex and already assembled, ready for sale.