Breadcrumb

Aluminium processing

Minifaber performs aluminum processing for the production of semi-finished and finished products.

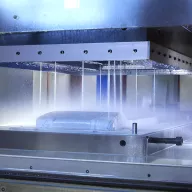

Aluminum processing includes a series of industrial procedures aimed at transforming this lightweight and durable metal into finished or semi-finished products. Among the main aluminum processes carried out by Minifaber are laser cutting, bending, welding, and finishing, used to create precise and robust components.

Processing can also include surface treatments, such as anodizing or painting, to enhance aesthetics and protective properties. It is a sustainable process, as aluminum is 100% recyclable.

Thanks to its lightness and versatility, aluminum is ideal for applications in electromechanics, medical, vending, and design sectors. We offer tailor-made solutions using cutting-edge technologies.

Different aluminium processing types

The main aluminum processing techniques carried out by Minifaber include:

- Laser cutting, which ensures precision, speed, and clean edges in aluminum processing, ideal for creating complex shapes.

- Bending, which allows the creation of angles, curves, and custom shapes using CNC press brakes.

- TIG welding, which provides strong joints and clean finishes, ideal for lightweight structures and aesthetic components.

- MIG welding, particularly suitable for thicker aluminum sections, ideal for carpentry and robust structural applications.

- Stamping, which allows the creation of complex shapes with high production volumes and excellent dimensional repeatability.

- Deep drawing, a specific metalworking technique that transforms aluminum sheets into hollow or convex shapes, ideal for aesthetic components and structural containers.

- Shearing, which uses dies to shape aluminum sheets, producing repetitive and precise parts in a short time.

- Punching, for making holes and shapes in aluminum sheets, with interchangeable tools and high-speed execution.

Each process is selected based on the thickness, aluminum alloy, and the final use of the part.

Production of aluminum semi-finished products

Aluminum processing for the production of semi-finished products includes specialized processes such as cutting, bending, welding, and surface finishing, ideal for creating components ready for further transformations.

Thanks to its lightness, corrosion resistance, and ease of processing, aluminum is the perfect material for applications in the electromechanical, construction, automotive, and furniture sectors.

Aluminum semi-finished products are manufactured with high precision, meeting tight tolerances and the customer's technical specifications. We offer customized solutions, using advanced technologies to ensure quality, speed, and reliability at every stage of processing. Contact us for a personalized quote for your projects.

Minifaber, professional aluminum processing services.

Contact us without obligation for more information

Applications of aluminum semi-finished products.

Expertise, passion and continuous technical advances allow us to work with the best companies in key application fields:

- ELECTROMECHANICAL

- FOOD PROCESSORS

- VENDING

- MEDICAL

- GAS DISTRIBUTION

- HOME/PROFESSIONAL APPLIANCES

- ENERGY DISTRIBUTORS

- PROFESSIONAL LIGHTING.

Minifaber, 65 years of cold metalworking know-how for small and large quantities.

Contact us for a quote and feasibility study

Aluminum molding: choose Minifaber for the creation of your molds

Aluminum molding is a process that allows you to obtain lightweight, resistant components with complex shapes, ideal for various industrial sectors. Thanks to the ductility of the material, it is possible to create custom parts, optimizing time and costs. The choice of alloy and the design of the mold are essential to guarantee quality and precision.

With over 65 years of experience in the sector, we are able to support you in the design phase of custom molds for the production of semi-finished and finished aluminum products. All the processing phases, from the design of the mold to the logistics management of the finished product, are carried out internally, with rigorous quality controls and qualified and specialized personnel.

We are ready to support you, contact us to speak with one of our technicians.