Moulds design and construction

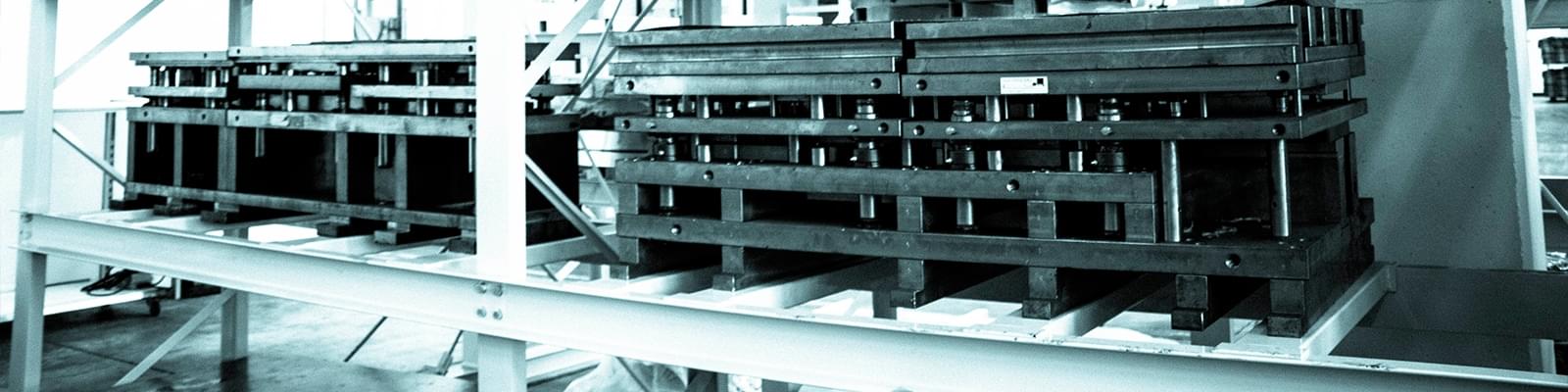

Minifaber has specific moulds design and construction know-how for sheet metal cold formingBolstered by its extensive experience in the cold forming field, Minifaber designs and manufactures moulds intended to cold form metallic alloys in-house.

Due to the expert Engineering Department and updated machinery, the company can custom design the mould to meet specific requests.

When a customer submits its request, the engineering-design staff sit around a table and listen to the demands, understand the needs, suggest improvements until the finished product that meets even the most complex needs is achieved.

All metal moulds are designed and manufactured to guarantee the best finished and semi-finished product. In the pursuit of waste minimisation and production precision, Minifaber employs computer systems able to interface and dialogue with the most modern operating systems available, that are used by the engineering-design staff to product and check mould designs during the design and subsequent production phases.

The high level of skills and complete machinery allow the company to design and construct any type of metal mould: blanking moulds, deep-drawing moulds, block moulds, progressive moulds, transfer moulds.

All moulds manufactured by Minifaber, certified as per international directives UNI EN ISO 9001:2008, are custom designed to provide the customer with maximum sheet metal cold forming production flexibility.

Specifically, Minifaber designs and manufactures the following metal moulds:

Shooting moulds

Shooting moulds are used to produce small quantities of components.

Progressive moulds

Progressive moulds (with built-in threading) are used to produce large quantities of components and are thus intended for heavy-duty work. They can create a finished product in a sequence of steps with a single mould and are thus able to achieve the best results in terms of product quality, production speed and cost savings.

Transfer moulds

They are used to create a finished product in a sequence of steps on a series of transfer connected moulds. Compared to progressive moulds, they provide higher processing freedom and work at a lower pace.

Deep-drawing moulds

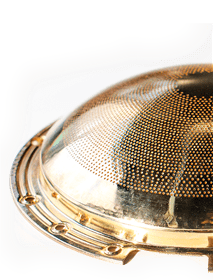

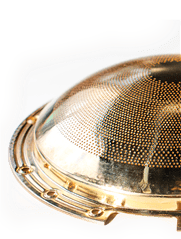

Deep-drawing moulds are used to manufacture square shaped, hollow, cylindrical, cup-shaped or other various shaped metallic parts and finished products. Required in every industry, Minifaber deep-drawing moulds guarantee the maximum precision and efficiency over time.

Minifaber designs and manufactures metal moulds for the following industries:

- Electromechanics

- Vending

- Kitchen robots

- Medical

- Gas distribution

- Professional lighting

- Home appliances

Minifaber has evolved to become the only company able to design and manufacture the complex, assembled end products no one else can.

Find out more