Sheet metalworking

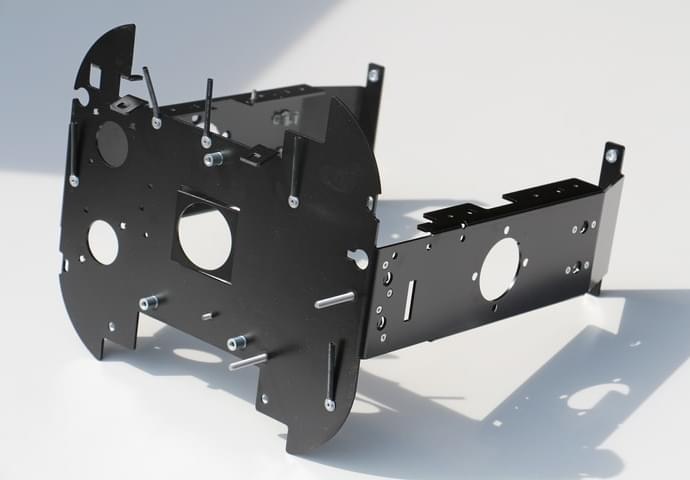

Minifaber cold processes both large and small quantities of metal. Skill, passion and continuous technical updates allow it to work with the best companies in the professional lighting, electromechanics, home appliance, medical, logistics and equipment industries.We carry out cold sheet metalworking in both large and small quantities: starting from the design and construction of molds and equipment for welding and assembly, we carry out all the most requested metalworking. The entire supply chain is carried out internally: our internal staff deals with the design, blanking, deep-drawing, bending, punching and welding of the pieces.

Find the following topics:

- What we do in sheet metalworking;

- How do we approach sheet metalworking process?

- Sheet metalworking tools;

- Why to choose Minifaber.

Types of sheet metalworking

Minifaber, for years recognized as one of the excellence for sheet metalworking, is able to produce any type of shape in press-folding. The experience of years and the use of high quality machinery for sheet metalworking, allow us to perform complex processes and offer innovative solutions.

Minifaber is able to perform the following types of sheet metal working:

- Sheet metal punching

- Sheet metal laser cutting

- Sheet metal welding

- Mold production

- Metal blanking

- Metal sheet bending

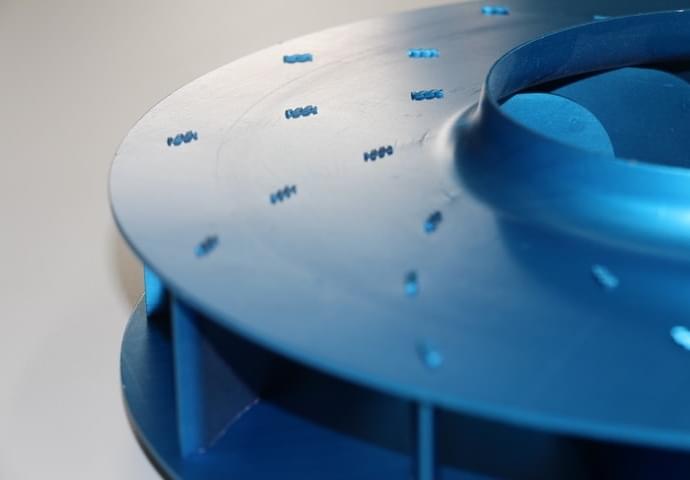

- Metal surface treatments

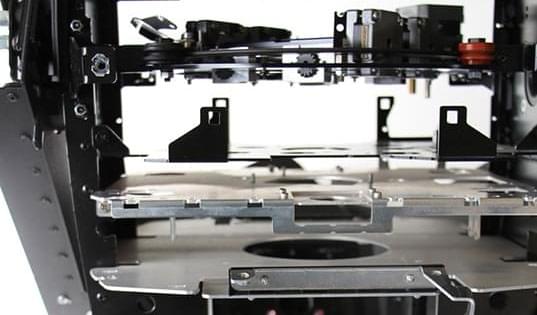

- Metal assemblies

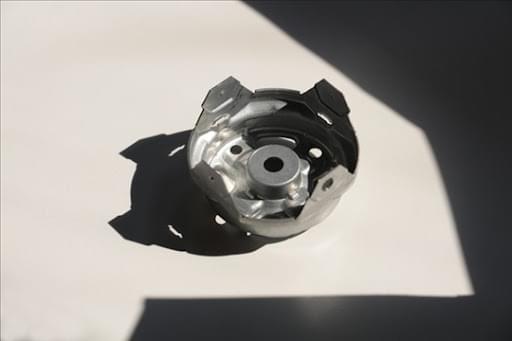

- Cold metal stamping

Sheet metal punching

Among sheet metal working, Minifaber can perform any metal punching operation, simple or complex. We can performpunching work on a wide selection of metals: iron, stainless steel, aluminum, copper, brass and special alloys. We do sheet metal cutting or drilling, producing precise and quality finished products.

Sheet metal laser cutting

Minifaber carries out any type of metal laser cutting, from the simplest to the most complex: four punching machines capable of cutting sheets up to 1250x2500 mm. This sheet metalworking can be done on aluminum, steel and stainless steel.

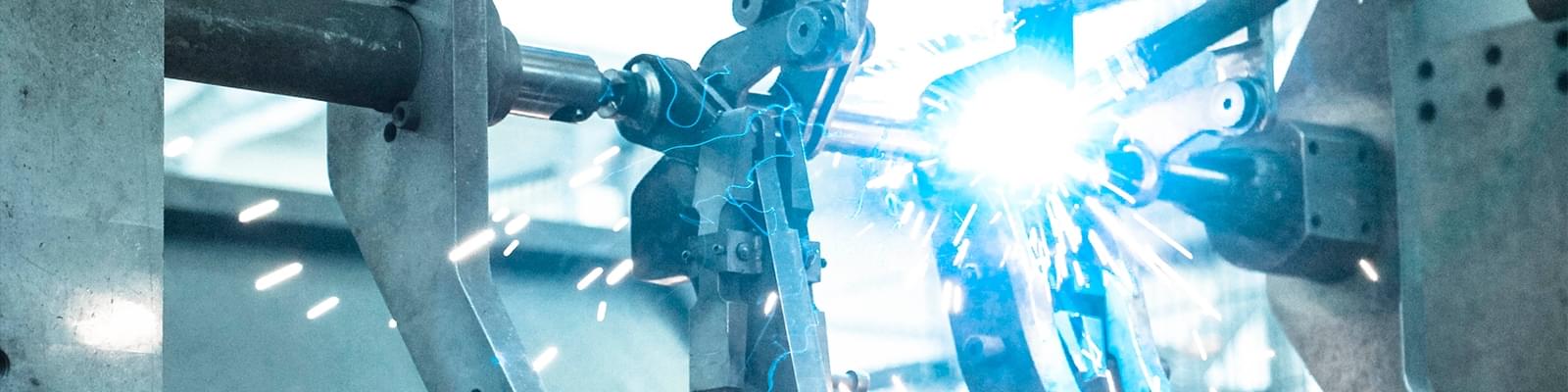

Sheet metal welding

Minifaber performs several types of sheet metalworking, including welding processes on various metallic and aluminum alloy surfaces as well as on stainless steel and iron. Specifically, we can perform:

- MIG welding

- TIG welding

- resistance welding

- projection welding

- robotic MIG and TIG welding

- laser welding

Mold production

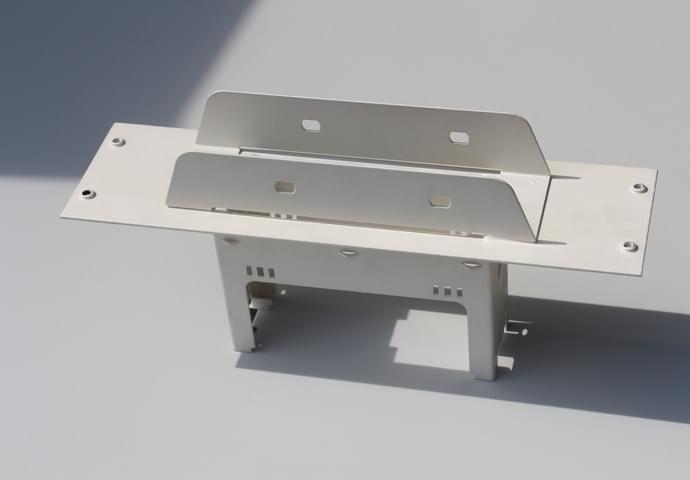

Due to its experience in sheet metalworking, Minifaber designs and manufactures dies in-house for cold forming of metal alloys. Thanks to its fleet of machines and technical team, the company can custom design the mold to meet specific customer requirements.

Metal blanking

Among sheet metalworking, Minifaber performs iron, aluminum, copper, stainless steel and special alloys blanking with the highest precision and up-to-date technologies. Metal stamping is done by shaping the sheet metal with punches, which deform and cut, and molds to give the shape.

Metal sheet bending

In sheet metalworking bending a machine, called the bender, exerts pressure on the flat plate by a mold, to obtain various shapes. Sheet metal bending can be used on metal surfaces to obtain finished semi-finished products. Minifaber can bend aluminum, steel and stainless steel, iron and copper.

Metal surface treatments

Minifaber is engaged in operating surface treatments on metals upon request. This sheet metalworking is effective in increasing metal strength and durability.

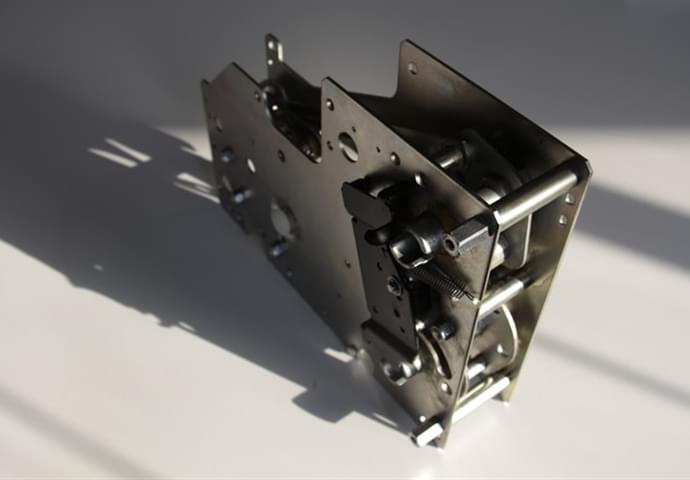

Metal assemblies

Minifaber is in the business of assembling metal components and to make finished products. Our company supplies tested and certified assemblies, semi-finished and finished products, even the most complex ones.

Cold metal stamping

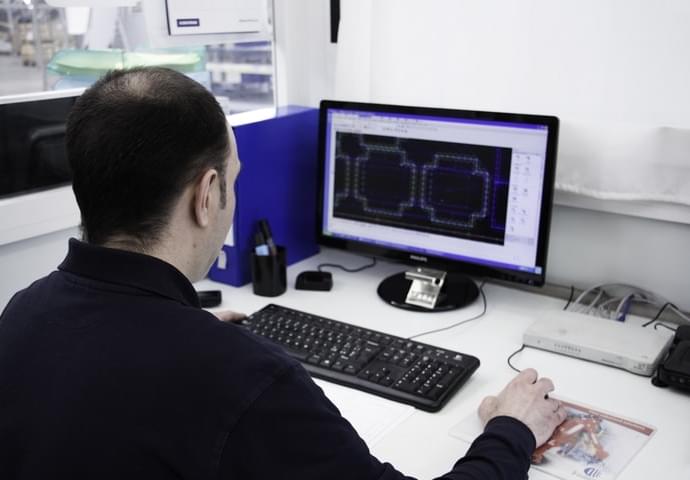

Minifaber carries out in-house sheet metal stamping from start to finish. We take care of the digital design of the molds up to the actual stamping and production of the finished or semi-finished product as required by the client.

How do we approach sheet metalworking process?

Our company works closely with clients to understand their needs and develop a product that fully reflects their goals. The first stage involves an interview to analyze the needs. In the second phase, our technical team is in charge of studying the feasibility and choosing the most suitable machinery and types of sheet metal working. After that, the actual processing, testing of manufactured products and delivery to the customer starts.

Sheet metalworking tools and machinery

Different tools and machines can be used in the sheet metalworking process. A first distinction can be done between hand tools and power tools. Hand tools include iron saws, drawing pins, blind riveting pliers, pliers, hammers, shell irons, file pistons, ejector pistols and so on. Power tools include clinching machines, drills, percussion drills, orbital, belt and random orbit grinders, soldering irons, lasers and so on.

Minifaber, 50 years of know-how in the cold sheet metalworking in small and large quantities

Competence, passion and continuous technical updating allow us to work with the best companies in the main sectors of application:

- Electromechanical

- Household appliances

- Medical

- Logistics

- Lighting technology

- Plant engineering

Minifaber can guarantee precision and flexible results in sheet metal working, due to its 50 years experience in the sector. By relying on our company you can count on:

- high operational knowledge at all levels of our organizational structure;

- fast and efficient processes thanks to the application of lean production;

- primary attention in respecting the delivery times.

Discover below all the sheet metalworking that we can provide:

-

Moulds design

-

Processing tool design and construction

-

Sheet metal fabrication

-

Metal blanking

-

Sheet metal deep drawing

-

Metal sheet bending

-

Sheet metal punching

-

Sheet metal laser cutting

-

Sheet metal welding

-

Metal surface treatments

-

Metal assemblies

-

Cold metal stamping

-

Sheet metal stamping

-

Steel bending

-

Metal welding

-

Stainless steel deep drawing