Sheet metal laser cutting vs plasma cutting: differences and similarities

A study of sheet metal cutting techniques, a list of advantages and disadvantages that can help you to choose the best cutting processing.

Both, laser cutting and plasma cutting are CNC technologies.

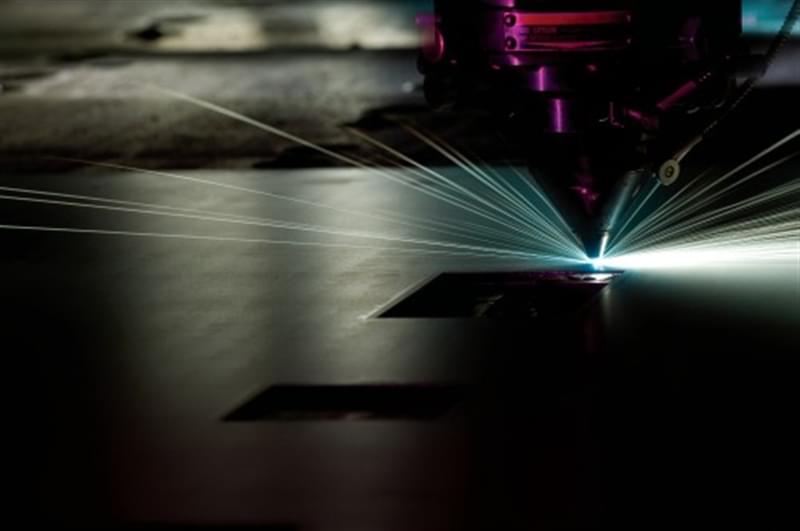

- Laser cutting works thanks to the beams of highly concentrated light that are generated from gas tubes

- Plasma cutting has spread to satisfy the cut of strongest metals (copper, aluminum and others) and, in short, is a transfer of energy able to transform gas like nitrogen o hydrogen and oxygen into plasma (a ionized gas). This plasma generates heat and transfers it to the sheet metal until the break point.

Despite they work with different methods, the sheet metal laser cutting and the plasma cutting can guarantee precision and excellent final results.

So, how to choose which one is the best for a specific situation? Let’s see it together!

Differences between laser cutting and plasma cutting

Plasma vs laser: we said that laser cutting uses light, instead plasma cutting works through gas; in practice, it means that:

- Laser boasts a higher precision. If you need to realize high-precision works on a big variety of sheets metals (such as stainless steel, aluminum, titanium etc) this is the method that, usually, is used. The sheets metal’s laser cutting is fundamental for all those industries that, despite the thickness of the materials need to cut with extreme precision (laser cutting is managed by software so the error rates are absolutely null) and to obtain exact copies of more pieces avoiding imperfections.

- In addition of being more precise, laser cutting allow you to save time and resources. Laser cutting on sheet metal is processed by specific software and it doesn’t need of human involvement.

- Last but not least, the sheets metal’s laser cutting reduces the contamination of work pieces because the cutting is made by a laser beam and there isn’t direct contact between sheet metal and any other material.

Are there disadvantages of laser cutting of sheet metal?

Oh yes. One of the main disadvantages of laser cutting is the cost of machines; they’re definitely more expensive compared to the plasma ones and they, generally, need more energy power. Furthermore, laser doesn’t let to cut thick sheet metal. In spite of this, this technique is more and more popular and appreciated thanks to the quality of final results.

Plasma laser cutter

Plasma laser cut is the other kind of processing that we consider in this article. For those who are looking for an efficient and low cost cutting method, plasma is perfect. In the last years, the quality of this technology has improved ensuring more defined results (especially for thinner sheets metal). Compared to laser cutting, plasma cutting is able to cut thicker sheet metal and a greater variety of metals. It arrives where other technologies don’t arrive and is also really easy to use.

The fact remains that with plasma you probably can’t obtain the same results for more than one piece and you are forced to consider secondary operations such as the finish of sheets metal.